In-Mold Decorations: Integrating Layout and Manufacturing Quality

In-Mold Decorations: Integrating Layout and Manufacturing Quality

Blog Article

Mastering In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Optimum Results

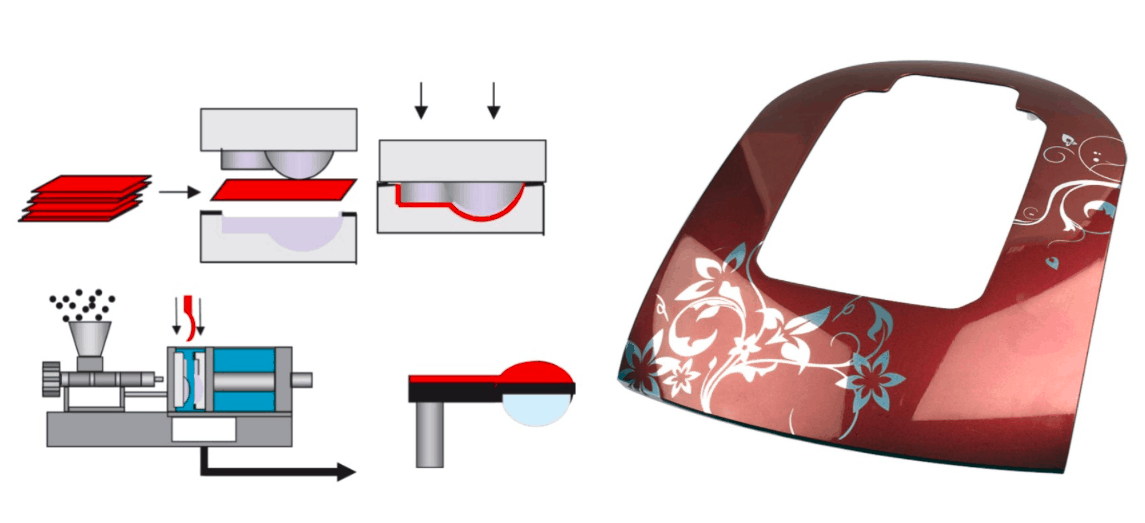

In the realm of manufacturing, the art of in-mold designs stands as a critical facet of product design and production. As markets constantly seek ingenious means to improve visual appeal and functionality, grasping the ins and outs of in-mold decors has become a vital ability set. From picking the best products to including cutting-edge layout trends, the trip in the direction of achieving optimal cause this domain is diverse. By diving right into the strategies, patterns, and ideal methods that underpin successful in-mold decoration procedures, businesses can unlock a world of possibilities that not just elevate the visual attraction of their items yet additionally simplify production performance and bolster customer engagement.

Material Selection

Material choice is a critical facet of grasping in-mold decorations, as it directly affects the high quality and sturdiness of the last item. When picking materials for in-mold decors, it is crucial to take into consideration variables such as compatibility with the molding process, the wanted aesthetic outcome, and the environmental problems the product will encounter.

Moreover, the chosen material needs to possess excellent bond residential properties to guarantee that the design sticks strongly to the substratum during the molding process. Adhesion between the design and the product is important for preventing delamination and making sure resilient visual allure. In addition, products with high heat resistance are favored for in-mold designs, specifically for products that will be exposed to raised temperature levels during their lifecycle. By meticulously picking the appropriate product for in-mold decorations, producers can boost the general quality and sturdiness of their items, satisfying the expectations of both customers and end-users.

Layout Development

An important aspect in progressing the field of in-mold designs is the continual expedition and execution of layout advancement strategies. Layout advancement plays an essential function in enhancing the visual charm, functionality, and general quality of items made using in-mold decor procedures. By integrating cutting-edge layout elements, producers can separate their products in the marketplace, attract consumers, and remain ahead of rivals.

One of the crucial elements of style advancement in in-mold decorations is the assimilation of detailed patterns, appearances, and graphics that were formerly testing to attain with traditional decoration methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to produce complicated and detailed styles that can be effortlessly moved onto shaped parts. In addition, using dynamic colors, metal coatings, and special results like gloss or matte structures can additionally elevate the visual charm of in-mold embellished items.

In addition, layout advancement extends past appearances to include useful improvements such as ergonomic forms, integrated attributes, and personalized elements that accommodate certain individual needs. By accepting style advancement, producers can unlock new opportunities for product, creativity, and personalization differentiation in the affordable landscape of in-mold decorations.

Production Efficiency

Reliable manufacturing procedures are essential for converting the innovative designs created in the area of in-mold designs Homepage into top notch finished products that satisfy market demands and consumer assumptions. In the realm of in-mold designs, production performance incorporates different key aspects that add to the overall success of the production procedure.

Automation not just speeds up the production process but likewise improves accuracy and repeatability, leading to a more consistent and top quality end item. In general, an all natural method to production effectiveness is critical in making the most of the capacity of in-mold decor strategies and accomplishing ideal outcomes in the competitive market landscape.

Quality Assurance Steps

What are the key approaches for guaranteeing strict quality control procedures in the world of in-mold decorations? Quality control measures are extremely important in in-mold decoration procedures to make certain the production of premium and remarkable ended up items.

Using innovative modern technologies such as automated evaluation systems can likewise enhance the quality assurance process by supplying precise and trusted information for evaluation. These systems can spot imperfections that may be missed by hands-on examinations, consequently enhancing overall item quality and uniformity.

Routine training and development programs for workers associated with the in-mold decor process can likewise add to maintaining high-quality standards. By educating personnel on best practices, high quality expectations, and the value of interest to information, firms can promote a culture of quality awareness throughout the company.

Customer Allure

To boost the bankability of in-mold decor items, providing and understanding to customer choices play an essential role in identifying their appeal and success. Customer charm in in-mold decorations is affected by different elements, consisting of layout aesthetics, shade options, durability, and overall performance. Customers are progressively seeking individualized and distinct items that show their originality and style. As a result, offering customization choices such as personalized styles, color variations, and textural elements can considerably enhance the charm of in-mold design products.

Final Thought

In-mold decors use a versatile and efficient means to enhance product aesthetics. Understanding in-mold decorations requires an all natural technique that thinks about their explanation all facets of the production process to make sure success.

In the world of manufacturing, the art of in-mold decorations stands as a critical element of item layout and manufacturing. Layout innovation plays an essential role in boosting the visual allure, performance, and total high quality of items made using in-mold decor procedures.One of the key aspects of design advancement in in-mold decorations is the integration of complex patterns, textures, and graphics that were previously challenging to achieve with conventional design methods.Effective production processes are vital for translating the cutting-edge designs established in the area of in-mold decors into high-grade finished products that fulfill market demands and consumer assumptions. Offering customization options such as tailored designs, shade variations, and textural aspects can considerably improve the appeal of in-mold decoration items.

Report this page